Optimization of Airlay Processes

OPAL- Optimization of Airlay Processes

BMBF project in the field of: “Mathematics for innovations in industry and services”

Participants

AM 3

- Eberhard Bänsch

- Stefanie Strunk

Department Mathematik (FAU)

- AM 1: Nicole Marheineke, Alexander Vibe

- AM 2: Guenter Leugering and Christoph Strohmeyer

External

- AGTM, TU Kaiserslautern: Axel Klar and Christian Nessler

- ITWM, Kaiserslautern: Raimund Wegener, Simone Gramsch, Dietmar Hietel

Industrial partners

- Autefa Solutions Germany GmbH

- IDEAL Automotive GmbH

Description

The Airlay Process is essential for the generation of lightweight components, which are used in many branches of industry. One example would be the goal of the automobile industry to reduce the weight of a car in order to save gas consumption.

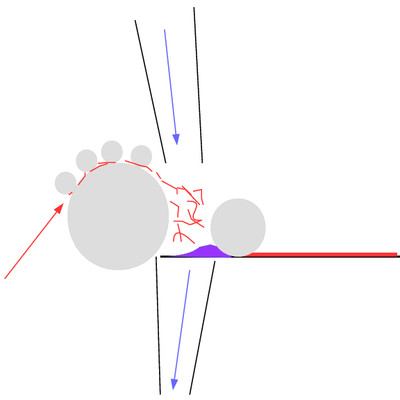

In the figure, on the right side, one can see the general concept behind this process. The fibers are colored in red. They are transported over a barrel into the turbulent air stream, which is symbolized with the blue arrows. The fibers are collected on a band-conveyor, where the enclosed air is removed with the help of another barrel. The fiber roving can now be further processed, e.g. stabilized, cut, etc. .

In the figure, on the right side, one can see the general concept behind this process. The fibers are colored in red. They are transported over a barrel into the turbulent air stream, which is symbolized with the blue arrows. The fibers are collected on a band-conveyor, where the enclosed air is removed with the help of another barrel. The fiber roving can now be further processed, e.g. stabilized, cut, etc. .

The goal in this project is to optimize the process in a form that it is possible to generate a certain profile of thickness in the resulting fiber roving so that the material loss is minimal if the material has to be cut in different forms. A second goal is to achieve certain material properties, like good acoustic damping.

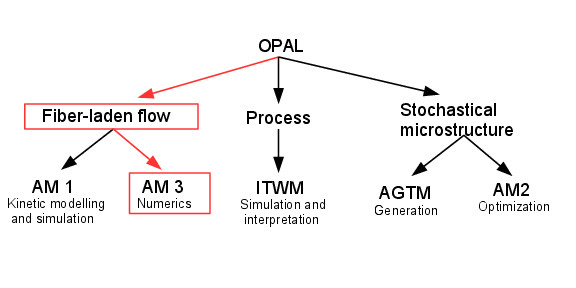

Structure

Our goal at AM3 is to develop a framework for the efficient simulation of fibers in a turbulent flow. To this end, an appropriate micro-macro model has to be developed and implemented.